The direct-acting steam pumps are very flexible machines. They can operate at any point of pressure and flow within the range of characteristics of the particular pump design.

The speed of the pump, and therefore the capacity of the pump, can be controlled from zero to maximum by a manually or automatically operated throttling valve on the steam supply.

The maximum speed is mainly limited by the frequency with which the valves will open and close smoothly.

The pump can operate against any system counter pressure, from zero to its maximum allowable working pressure.

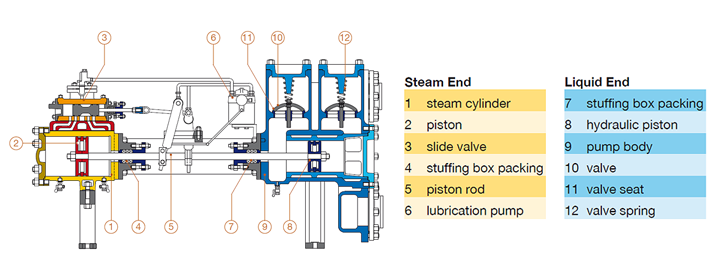

In a specific application, however, the hydraulic end maximum pressure may be limited by the available steam pressure and by the ratio of the steam piston and liquid piston areas.

A common characteristic of both Vesuvio and Vulcano steam driven pumps is the very low value of the NPSHr.

In fact, the liquid end of these pumps is designed to maximize all the passages of the fluid flow, specifically in the valves area. Additionally, the pumps are always selected to operate at a very low speed.

For this reason, one of the main applications of the steam driven pumps is the pump-out service in the Refineries, where the NPSH available is often low and the fluids handled are miscellaneous hydrocarbons often with high viscosity and high temperature.